Industry standard for UV curing trifunctional monomer-TMPTA

SINOMER® TMPTA(Trimethylolpropane triacrylate) as a low-viscosity trifunctional reactive monomer, widely used in ultraviolet light curing and electron beam curing coatings, inks, adhesives and other fields. The product is currently no national standards or industry standards, in order to improve and ensure the quality of light curing and electron beam curing active monomer products, to promote the development of light curing and electron beam curing industry, the development of this industry standard.

This standard is based on the quality of the products of the main domestic and foreign producers of active monomer. This standard is based on GB/T1.1-2000 “standardization guidelines Part 1: standard structure and numbering rules” and GB/T1.2-2002 “standardization guidelines Part 2: the content of the normative technical elements of the standard determination method” preparation.

This standard is proposed by the Chinese Society of Photoreceptors radiation curing special committee. This standard by the Chinese Photoreceptor Society of radiation curing special committee under the mouth. This standard drafting unit:Sinocure Chemical Co.,Ltd.

1 Scope

This standard specifies the technical requirements of trimethylolpropane triacrylate (referred to as TMPTA Monomer), test methods, inspection rules and marking, packaging, transportation and storage.

This standard applies to trimethylolpropane and acrylic acid in the catalyst under the action of esterification reaction and obtained TMPTA.

Molecular formula: C15H20O6

Molecular weight: 296.15 (according to 1999 international atomic weight table)

2 Normative application documents

The provisions in the following documents become the provisions of this standard by reference to this standard. All subsequent revision sheets (excluding errata) or revised versions of any document dated by reference do not apply to this standard. However, parties to an agreement under this standard are encouraged to investigate the use of the latest version of these documents. Where the reference documents are not dated, their latest versions are applicable to this standard. GB/T 601-2002 Chemical reagents Preparation of standard titration solutions

GB/T 602-2002 Chemical reagents Preparation of standard solutions for impurity determination

GB/T 603-2002 Chemical reagents Preparation of preparations and products used in test methods

GB 4472-84 Density of chemical products General rules for the determination of relative density

GB/T 5561-94 Surfactants Determination of viscosity and flow properties by rotary viscometer

GB 6283-86 Determination of moisture content in chemical products Fisher method (general method)

GB/T 6678-2003 General rules for sampling chemical products

GB/T 6680-2003 General rules for sampling liquid chemical products GB 6682-92 Analytical laboratory water specifications and test methods

GB 8170-1987 Numerical modification rules

GB 9282-88 transparent liquids with platinum – cobalt grade color assessment

GB/T 9750-1998 Coating product packaging mark

GB/T 17530.5-1998 Determination of polymerization inhibitors in industrial acrylic acid and esters

JJF1070-2005 quantitative measurement of the net content of packaged goods inspection rules

General Administration of Quality Supervision, Inspection and Quarantine Order [2005] No. 75 supervision and management of the measurement of quantitative packaging goods

3 Technical requirements

3.1 Product requirements should comply with the technical requirements listed in Table 1.

3.2 Net content shall comply with the General Administration of Quality Supervision, Inspection and Quarantine Order [2005] No. 75 “Supervision and Administration of Quantitative Packaging Commodity Measurement” provisions.

Table 1 Technical indicators of trimethylolpropane triacrylate

| Item | Indicator |

| Appearance | Clear liquid |

| Density (25 ℃, g/cm3) | 1.0900-1.1200 |

| Color(Hazen unit) ≤ | 50 |

| Purity(GC%) ≥ | 83 |

| Organic solvent content (GC%) ≤ | 0.50 |

| (Toluene) (GC%) ≤ | 0.2 |

| Acid value (mgKOH/g) ≤ | 0.3 |

| Moisture content (%) ≤ | 0.15 |

| Viscosity (cps, 25℃) | 70~110 |

| Methanol test (1:20) | Clarity and transparency |

| Polymerization inhibitor (by MEHQ) | ppm 100~400 |

4. Test method

The standard reagents and water used in the absence of other special requirements, are used in the analytical purity of reagents and GB / T 6682 in the provisions of the three levels of water. Standard titration solutions, preparations and products used in the test, in the absence of other requirements, are prepared in accordance with the provisions of GB / T 601, GB / T 602, GB / T 603.

4.1

Appearance Visual inspection under natural light.

4.2 Density

Measured according to the provisions of GB 4472.

4.3 Color

Measured according to GB 9282.

4.4 Purity (%)

Gas chromatography, measured according to the provisions of HB/FG03-2009.

4.5

Organic solvent content (toluene) Gas chromatography, according to the provisions of HB/FG04-2009 for the determination.

4.6 Acid value

4.6.1 Instrument

4.6.1.1

Microburet: 1~2 mL, 0.01 mL; 4.6.1.2 Conical flask: 125 mL. 4.6.2 Reagents 4.6.2.1 Sodium hydroxide: C (NaOH) = 0.05 mol/L standard solution; 4.6.2.2 Phenolphthalein: 10 g/L ethanol solution.

4.6.3 Operation steps

4.6.3.1

Take 50 mL of anhydrous ethanol, add 2 drops of phenolphthalein indicator of 10 g/L, neutralize with 0.05 mol/L sodium hydroxide solution until slightly red, and set aside.

4.6.3.2

Weigh 5 g of sample (accurate to 0.0001 g) in a 125 mL conical flask, add 25 mL of neutralized ethanol, add 2 drops of phenolphthalein indicator (10 g/L), and titrate with 0.05 mol/L NaOH standard solution until pink (no fading within 30 seconds) is the end point.

4.6.4 Calculation

The acid value of the sample mgKOH/g (X) is calculated according to the following formula.

X=![]()

Where: V – volume of sodium hydroxide standard solution consumed for titration of sample solution, mL; C – concentration of sodium hydroxide standard solution, mol/L; m – mass of sample, g; 56.11 – molar mass of potassium hydroxide, g/mol.

4.7

Moisture content Measured according to GB 6283.

4.8

Viscosity Determination according to GB/T 5561-1994.

4.9 Methanol test

4.9.1 Reagent

4.9.1.1

Anhydrous methanol, AR grade 4.9.2 Apparatus

4.9.2.1 Colorimetric tube (50 mL)

4.9.2.2 Operation procedure

Measure 1.0 mL of sample in 50 mL cuvette, then add 20.0 mL of anhydrous methanol and shake well, do the blank test at the same time, then compare the sample with the blank test, the sample should be clear and transparent.

4.10 Content of MEHQ as a polymerization inhibitor

Measured according to the provisions of GB/T 17530.5.

4.11 Net content

Measured according to the provisions of JJF 1070.

5 Inspection rules

5.1 The products shall be inspected by the quality inspection department of the company according to this standard before leaving the factory, and accompanied by the product certificate of conformity.

5.2 Each production batch of the product as a test batch, according to GB / T 6678, GB / T 6680 sampling, the sample is divided into two copies, one sealed and stored as a reserved sample, and the other for testing.

5.3 all indicators tested in accordance with the standard requirements is judged to be qualified, when an indicator does not meet the requirements, the sample should be redoubled for the failed items for retesting, retesting still failed, the batch is judged to be unqualified.

6 logo, labeling, packaging, transportation, storage

6.1 Logo According to the provisions of GB / T 9750 implementation.

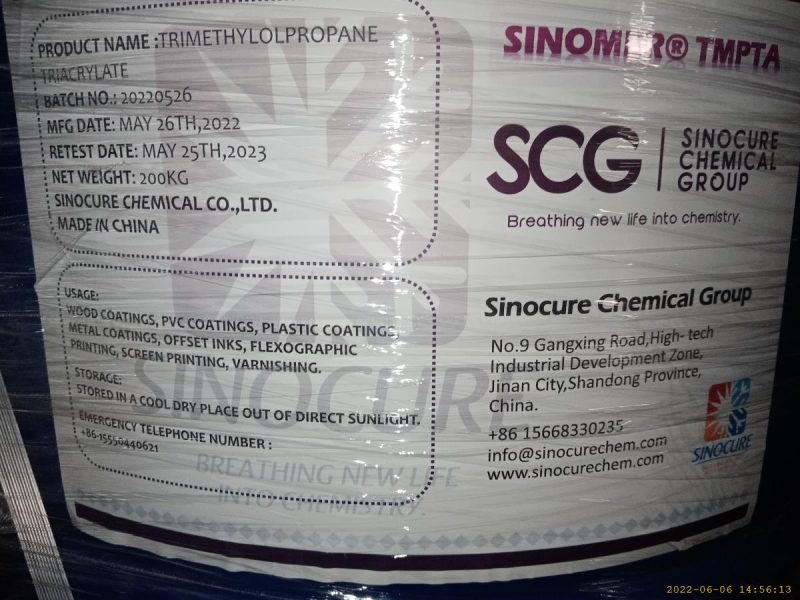

6.2 Labeling The product should be accompanied by a label mark, indicating the product name, lot number, net content, manufacturer’s name and address, production date, shelf life, certificate of compliance, implementation standards and warning tips.

6.3 Packaging In accordance with the provisions of GB / T 13491.

6.4 Transportation Avoid direct sunlight exposure during transportation.

6.5 Storage The product should be stored at room temperature away from light.

7 Expiration date The product is valid for 12 months from the date of manufacture, beyond the expiration date, according to the items specified in this standard re-inspection, if it meets the technical requirements, can still be used.