SINOMER® PETMP: High-Performance Thiol-Ene Curing Agent for Acrylic Resins

Introduction

SINOMER® PETMP (Pentaerythritol Tetrakis(3-mercaptopropionate)) is a tetrafunctional thiol curing agent engineered for advanced acrylic resin systems. Leveraging rapid thiol-ene click chemistry, it enables fast curing, ultra-low shrinkage, and exceptional optical clarity, making it ideal for applications in electronics, optics, and 3D printing.

Key Advantages

- Ultra-Fast Curing: Achieves full cure in seconds to minutes under UV/thermal initiation.

- Near-Zero Shrinkage (<2%): Minimizes stress in precision applications like microelectronics.

- High Transparency: UV-stable, colorless cured films (ΔB <1.0 after 500h QUV testing).

- Versatility: Compatible with UV/thermal systems and hybrid formulations (e.g., epoxy-thiol).

Mechanism: Thiol-Ene Click Chemistry

SINOMER® PETMP’s four reactive thiol (-SH) groups undergo radical-mediated thiol-ene reactions with acrylic double bonds, offering:

- High Conversion Rates: >95% monomer conversion, reducing residual volatiles.

- Oxygen Inhibition Resistance: Surface cure quality comparable to nitrogen-purged systems.

- Flexibility Control: Adjust crosslink density by tuning acrylate/PETMP ratios.

Applications in Acrylic Resin Systems

1. Optical Adhesives & Coatings

- Use Case: Bonding smartphone screens or AR/VR lenses.

- Performance:

- Refractive index: 1.48–1.50 (matches glass/acrylic substrates).

- Light transmission: >99% at 450 nm (ASTM D1003).

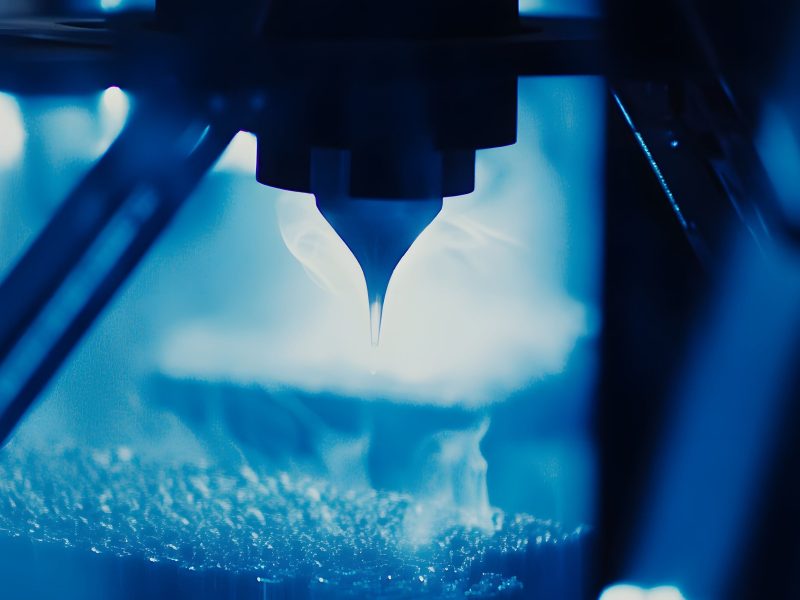

2. 3D Printing Resins

- Use Case: High-resolution dental models or microfluidic devices.

- Benefits:

- 50% faster print speeds vs. traditional acrylates.

- <1% warpage due to low shrinkage.

3. Electronic Encapsulants

- Use Case: Potting for LED modules or sensors.

- Thermal Stability: Withstands -40°C to 150°C thermal cycling (MIL-STD-883).

Technical Specifications

| Property | SINOMER® PETMP | Industry Standard Thiols |

|---|---|---|

| Viscosity (25°C) | 300–500 mPa·s | 800–1,200 mPa·s |

| Thiol Equivalent | 140–160 g/eq | 180–220 g/eq |

| Odor Level | Low (maskable) | Strong mercaptan odor |

| Storage Stability | 12 months at 25°C | 6–8 months |

Formulation Guidelines

| Component | Role | Ratio (%) |

|---|---|---|

| Acrylate Resin | Base oligomer | 70–80 |

| SINOMER® PETMP | Curing agent | 15–25 |

| Photoinitiator (e.g., TPO) | UV activation | 1–3 |

| Additives | Flow agents, fillers | 2–5 |

Process:

- Mix components at 25°C under low-light conditions.

- Cure under UV (365 nm, 500–1,000 mJ/cm²) or heat (60°C, 10–30 min).

Case Study: Optical Adhesive for AR Glasses

- Challenge: Delamination due to thermal stress in AR lens assemblies.

- Solution: Switched to SINOMER® PETMP-based adhesive.

- Results:

- 0% delamination after 1,000 thermal cycles (-30°C to 85°C).

- Production throughput increased by 35% via 20-second UV curing.

Why Choose SINOMER® PETMP?

- Cost Efficiency: 20% lower formulation costs vs. specialty acrylates.

- Regulatory Compliance: REACH/RoHS-certified, halogen-free.

- Technical Support: Custom formulation assistance from Sinocure’s R&D team.

Upgrade Your Acrylic Formulations Today

Enhance curing speed and precision with SINOMER® PETMP.

📧 Email: info@sinocurechem.com | 📞 Tel: +86 15668330235