The first choice epoxy resin curing agent for low temperature and rapid curing

Adhesives are formulated with binder as the main agent and various curing agents, plasticizers, fillers and other additives. They are closely related to our daily lives and can effectively bond contact surfaces of the same material or even contact surfaces of different materials. , usually used for bonding handicrafts, furniture repair, glass sealing, packaging, etc. In addition to traditional application fields, adhesives have broad prospects for development in emerging application fields such as wind power, electronic appliances, aerospace, etc. At present, under the guidance of relevant policies, adhesive products are gradually developing towards high performance and environmental protection, and the new application range of adhesives is wider.

According to different molecular structures, adhesives can be divided into silicone adhesives, polyurethane adhesives, hot melt adhesives, epoxy resin adhesives, etc. Among them, epoxy resin adhesives can bond metals and most non-metallic materials and are widely used. Used in construction, automobiles, electronics, electrical appliances and daily household products. For example, in the field of electronic and electrical packaging, epoxy resin potting glue has the characteristics of small shrinkage, good heat resistance and electrical insulation properties, and good sealing properties. It can be used as a good packaging material to improve the convenience of packaging. At the same time as the success rate, it can also improve the durability of the package. Therefore, epoxy resin potting adhesive is the most widely used adhesive product in the field of electronic and electrical packaging.

Epoxy resin itself is a thermoplastic resin with a linear structure and its performance is very stable. Only by adding a curing agent to cross-link it from the linear structure into a network or three-dimensional structure can it have excellent performance and the performance of the cured product is very high. The degree depends on the curing agent, so the curing agent is an essential component in the use of epoxy resin. There are many types of epoxy resin curing agents. Only by matching the appropriate curing agent according to different usage scenarios can the best performance of the epoxy resin system be exerted.

Epoxy resin curing agents are mainly divided into two types: explicit and latent types. Explicit curing agents are usually commonly used curing agents and are generally divided into amines, acid anhydrides, phenolics, alkyd resins, and polythiols. etc. This type of curing agent either performs addition polymerization by opening the ring of the epoxy group and participates in the three-dimensional network structure itself, or performs ring-opening addition polymerization of the epoxy group in an anionic and cationic manner and does not participate in the network structure itself. ; Latent curing agent means that after being mixed with epoxy resin, it remains stable under certain conditions, but when it is exposed to special conditions (such as light, heat, moisture, etc.), a curing reaction begins.

At present, in order to meet the needs of resin modification, the development of functional curing agents with excellent properties such as rapid curing, low-temperature curing, toughening, and flame retardancy, as well as low-toxic, non-toxic curing agents and curing agents adapted to special environments has become the focus of the market.Polythiol is one of the functional curing agents. With the help of appropriate accelerators (such as tertiary amines), the speed of the curing reaction can be increased to several times that of polyamine curing agents. Therefore, polythiol is irreplaceable in certain specific fields.For example, it can be quickly cured in a low temperature environment of about -10°C, so it is suitable for outdoor construction adhesives in winter; its characteristics of rapid hardness development, low toxicity/non-toxicity, and resistance to yellowing also allow it to be consumed in “5 minutes” It has been widely used in adhesives and quick repair adhesives; its advantages in mechanical properties such as strong adhesion and good toughness also determine its important position in epoxy resin curing agents. In addition, because polythiol curing agents contain sulfur flexible segments and have high refractive index, they also have great application value in transparent resins and toughened resins.

SINOCURE Polymercaptan/Polythiol series product introduction:

| Product Name | Cas No. | Chemical Name | Synonyms |

| ▶Sinomer® PETMP | 7575-23-7 | Pentaerythritol tetrakis(3-mercaptopropionate) | THIOCURE PETMP;

PET-3-MP;Tetra (3-mercaptopropionate) |

| ▶Sinomer® BMES | 3570-55-6 | Bis(2-mercaptoethyl) sulfide;

Dimercapto diethyl sulfide; 2,2′-Thiodiethanethiol; |

THIOCURE DMDS;

Polythiol DMDS |

| ▶Sinomer® BMPT | 131538-00-6 | 2,3-bis((2-mercaptoethyl)thio)-1-propanethiol | THIOCURE DMPT;

Polythiol DMPT |

| ▶Sinomer® PM839 | 72244-98-5 | Poly[oxy(methyl-1,2-ethanediyl)],.alpha.-hydro-.omega.-hydroxy-, ether with 2,2-bis(hydroxymethyl)-1,3-propanediol (4:1), 2-hydroxy-3-mercaptopropyl ether | Capcure 3-800;

GABEPRO GPM-800; Polythiol QE-340M; Thiocure 1200 |

SINOMER PM839 is a low-temperature rapid curing agent for epoxy resin. Its appearance is colorless or light yellow transparent liquid. The viscosity range is 12000~14000 mPa·s at normal temperature (25℃). The sulfhydryl content is ≥12 and the chromaticity is ≤20. It can be used in 5 minutes AB glue, electronic adhesive, metal epoxy putty, electronic thermal conductive glue, anti-corrosion coating, silicon rod cutting glue and other application fields. Among them, The silicon rod cutting adhesive generated by SINOMER PM839 has high bonding strength and flexibility after curing, which can reduce defects such as falling pieces, edge chips and cracks during the silicon rod cutting process, thus improving the yield of silicon rod cutting itself.

After the cutting of the silicon rod is completed, the adhesive-coated silicon wafer can be quickly and easily detached by soaking it in warm water. Clean energy sources such as the photovoltaic industry are in a period of vigorous development, and the requirements for fine cutting technology will continue to increase, which will inevitably lead to rapid growth in demand for silicon rod cutting glue.

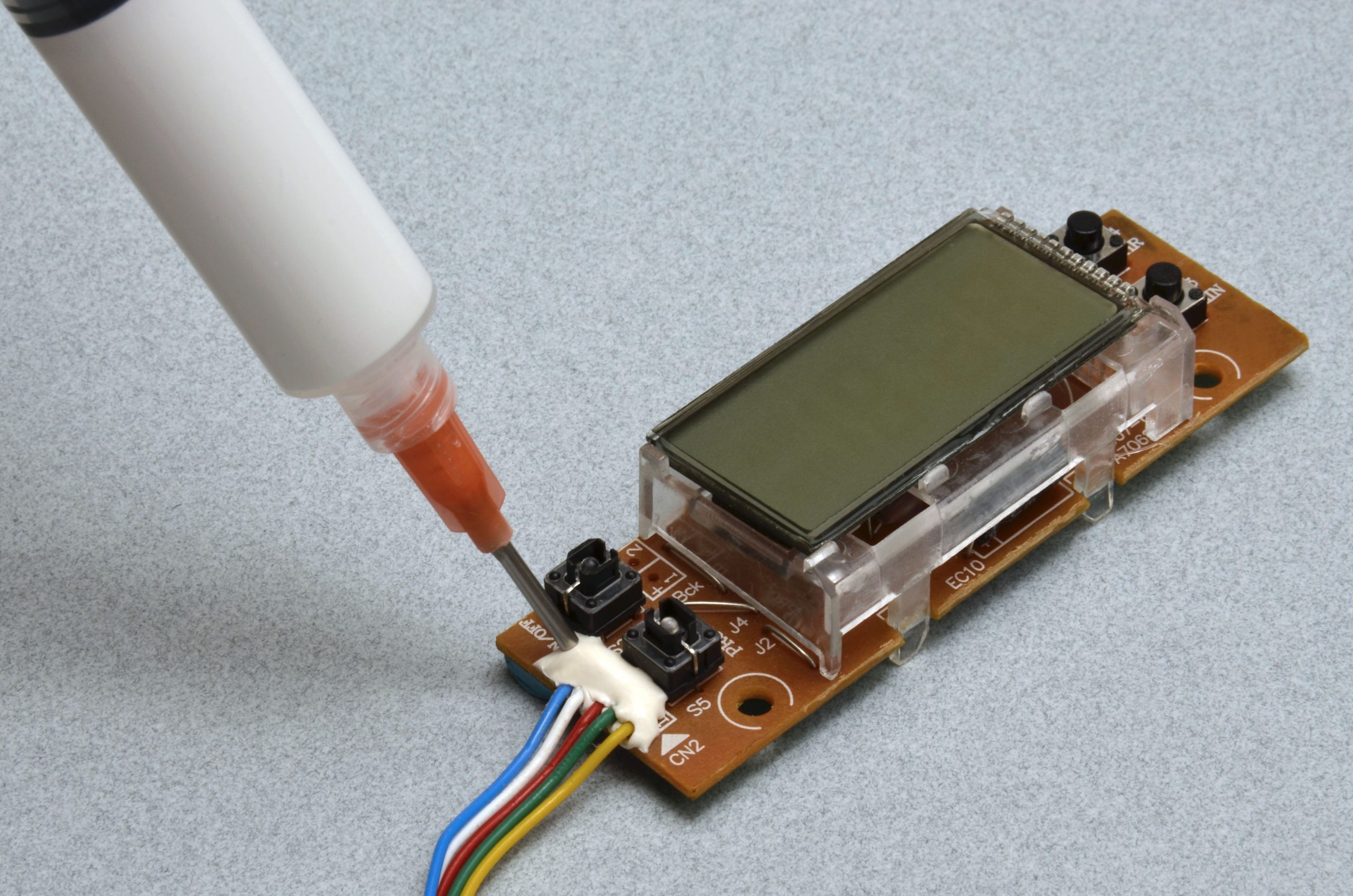

In addition, SINOMER PM839 can also be used to generate packaging adhesives. Packaging is an important process in the production process of electronic appliances. It is mostly non-detachable. Therefore, the failure of packaging means the scrapping of the product, which will have a negative impact on the production of the company. In the packaging process of electronic components, packaging adhesives can protect electronic components. They can not only prevent moisture, dust, harmful gases and other factors from corroding electronic devices or circuit boards, but also slow down or offset the damage caused by external forces and vibrations, thereby improving the stability of electronic devices. As the demand for electronic and electrical products such as smartphones and smart homes continues to grow, the continued and steady expansion of China’s electronic product market will drive a steady increase in the demand for adhesives in electronic and electrical products.

SINOMER PETMP—tetrakis (3-mercaptopropionate) pentaerythritol ester, is a fast-curing polythiol curing agent that can be used in orthodontic adhesives, quantum dot films, 3C electronic glue, and UV optics glue, and other high-end adhesive fields. However, the odor problem of polythiols has always troubled downstream customers. SINOCURE has now launched odorless SINOMER PETMP products, further expanding the product’s application fields and meeting the more diversified needs of customers.

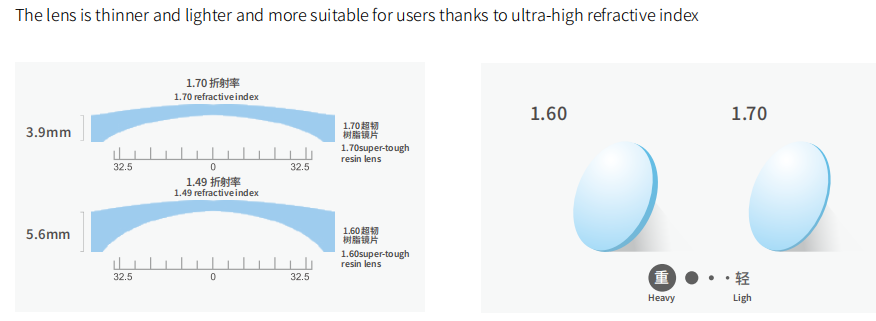

SINOMER® BMES (Cas No.3570-55-6) has features of low chrominance, low moisture content, low viscosity and High refractive index, super light and thin, and high-definition.

Application areas:

• Glasses lens material monomer of 1.70 high refractive index

• Special anticorrosive coating

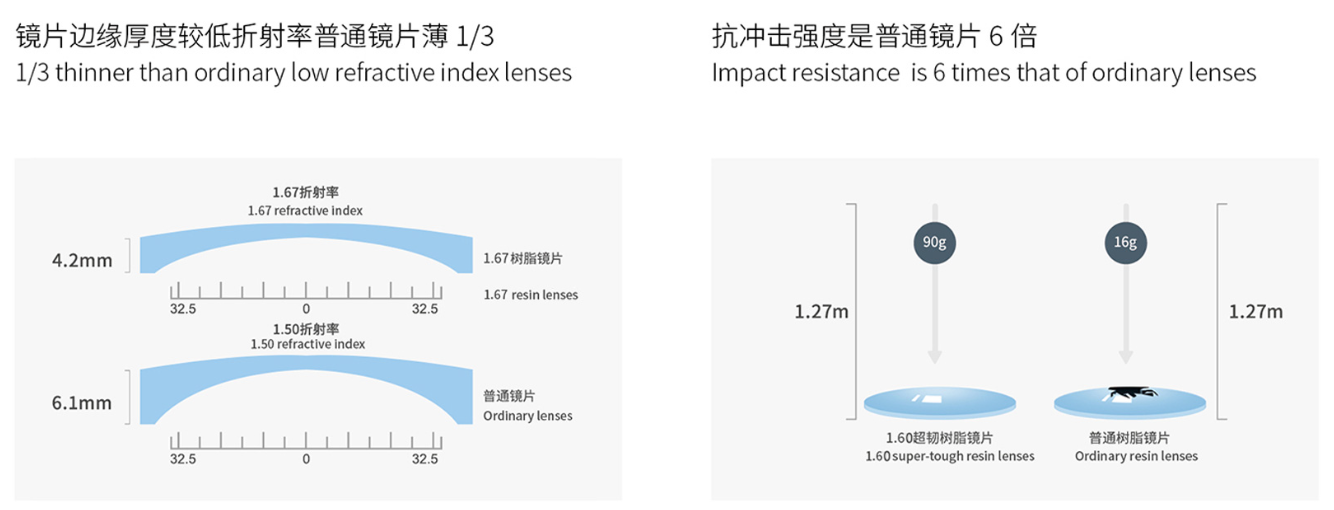

SINOMER® BMPT(CAS No.:131538-00-6) has the features of :

• High refractive index, high definition, high Abbe, and strong resistance to impact

• Ultra-light and thin, good dyeing property, and applicable to design of precision progressive lens

Application areas:

• 1.67 HRI glasses lens monomer

• HRI optical lens element

• Precision optical lens processing

Since its establishment, SINOCURE has always adhered to technology-driven industrial development, providing optical materials with sulfur as the core for the fluoroscopic health ecological appliance industry, and realizing a high value-added product line layout, with terminals covering optometry, electronics, biomedicine, and new energy. and other national key support areas, and its products are exported to more than 20 countries and regions including the United States, Italy, the Netherlands, Japan, South Korea, Central Asia, and Southeast Asia.