LAP is a blue light initiator. Under the action of blue light, LAP rapidly triggers the curing of photosensitive hydrogel materials. Compared with UV photoinitiators, blue light is less damaging to cells, so LAP is more suitable for curing cell-containing hydrogels. In recent years, blue light curing has been widely used in bio-3D printing containing cells.

1. Chemical Properties

Chemical Formula: C18H18LiO2P

Molecular Weight: 300.2 g/mol

CAS Number: 85073-19-4

Appearance: Typically appears as a white to off-white powder.

2. Synthesis

LAP is synthesized through the reaction of phenylphosphonic dichloride with 2,4,6-trimethylbenzoyl chloride in the presence of a base, followed by lithiation. The process involves:

Reaction of Phenylphosphonic Dichloride: The initial step involves reacting phenylphosphonic dichloride with an appropriate base to form an intermediate.

Addition of 2,4,6-Trimethylbenzoyl Chloride: The intermediate is then reacted with 2,4,6-trimethylbenzoyl chloride to form the desired phosphinate compound.

Lithiation: Finally, the compound is lithiated to produce LAP.

3. Applications

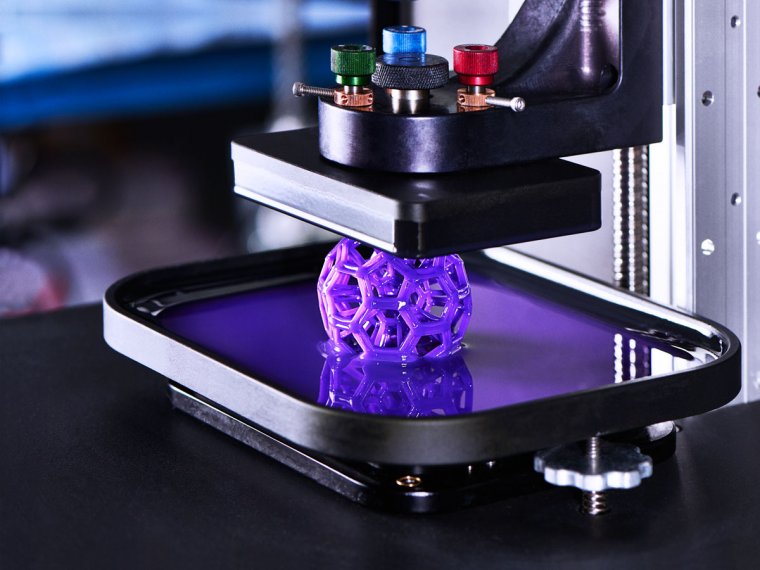

1) 3D Printing

LAP is a critical component in the realm of additive manufacturing, particularly in SLA and DLP technologies.

Stereolithography (SLA): In SLA, a laser is used to cure and solidify photopolymer resin layer by layer. LAP’s high reactivity under UV light ensures rapid polymerization, enhancing the speed and precision of the printing process. The use of LAP in SLA results in high-resolution prints with fine details and smooth surface finishes.

Digital Light Processing (DLP): DLP uses a digital projector to flash a single image of each layer across the entire platform, curing the resin simultaneously. LAP’s efficiency in initiating polymerization leads to shorter exposure times and faster build rates, making it ideal for high-throughput production. Additionally, the low yellowing characteristic of LAP ensures that the printed objects maintain clarity and color fidelity.

2) Dental Materials

In dental applications, LAP plays a pivotal role in the formulation of various light-curable materials.

Dental Composites: LAP is used in composite resins for dental restorations. These materials require quick curing to minimize chair time for patients. LAP provides rapid polymerization under dental curing lights, resulting in durable and aesthetically pleasing restorations with high mechanical strength.

Orthodontic Adhesives: For bonding orthodontic brackets, light-curable adhesives containing LAP offer strong adhesion and fast curing times, improving the efficiency of the bonding process and enhancing patient comfort.

3) Coatings

LAP is integral to the development of UV-curable coatings used across multiple industries.

Automotive Coatings: UV-curable coatings containing LAP provide robust protection against environmental factors such as UV radiation, chemicals, and mechanical wear. These coatings cure rapidly, improving production efficiency and reducing downtime in automotive manufacturing.

Electronics Coatings: In the electronics industry, LAP-based UV-curable coatings are used to protect circuit boards and other components from moisture, dust, and other contaminants. The quick curing time and excellent adhesion properties of LAP-based coatings ensure the reliability and longevity of electronic devices.

Furniture and Wood Finishes: LAP is used in UV-curable varnishes and finishes for furniture and wood products. These coatings offer superior hardness, scratch resistance, and aesthetic appeal, enhancing the durability and visual quality of the finished products.

4) Adhesives

UV-curable adhesives formulated with LAP find applications in various sectors due to their strong bonding properties and rapid curing.

Electronics Assembly: In the assembly of electronic devices, precise and reliable bonding is essential. LAP-based adhesives cure quickly under UV light, providing strong bonds without the need for heat or additional curing agents. This reduces thermal stress on sensitive electronic components.

Medical Devices: For medical device assembly, LAP-based adhesives ensure biocompatibility and strong adhesion to various substrates, including metals, plastics, and ceramics. The rapid curing times enhance manufacturing efficiency and reduce the risk of contamination.

Optics and Photonics: In the production of optical components and photonic devices, LAP-based adhesives offer clarity and minimal yellowing, ensuring high performance and reliability of the assembled products.

5) Inks and Printing

LAP is also used in UV-curable inks and printing applications.

Packaging: UV-curable inks containing LAP are employed in the printing of packaging materials. These inks offer fast curing, high print quality, and resistance to smudging and abrasion, ensuring durable and vibrant prints on packaging.

Graphics and Signage: For large-format printing, such as billboards and signage, LAP-based inks provide excellent color consistency and adhesion to various substrates, including vinyl, plastics, and metal. The rapid curing process allows for quick turnaround times in production.

4. Advantages

1) High Reactivity

Fast Curing: LAP exhibits high reactivity to UV light, which translates to rapid curing times. This is particularly beneficial in industrial applications where speed and efficiency are crucial. For example, in 3D printing and coatings, fast curing leads to increased throughput and reduced production times.

Efficient Polymerization: The high absorption coefficient of LAP in the UV range ensures efficient initiation of polymerization. This results in a more complete cure of the material, enhancing the mechanical properties and durability of the final product.

2) Low Yellowing

Maintains Clarity: One of the key advantages of LAP over other photoinitiators is its ability to minimize yellowing during and after the curing process. This is particularly important in applications where aesthetic quality and color stability are critical, such as in dental restorations, clear coatings, and optical adhesives.

Enhanced Aesthetics: Low yellowing ensures that the cured products maintain their intended appearance over time, which is essential for applications in the electronics, automotive, and packaging industries where visual quality is a key consideration.

3) Versatility

Compatibility with Various Monomers and Oligomers: LAP is compatible with a wide range of monomers and oligomers, making it a versatile choice for formulating different types of UV-curable resins. This allows manufacturers to use LAP in diverse applications, from flexible coatings to rigid plastics.

Adaptability to Different Processes: LAP can be used in various curing processes, including free radical and cationic polymerization. This adaptability makes it suitable for a broad spectrum of industrial applications, from 3D printing and coatings to adhesives and inks.

4) Improved Mechanical Properties

Enhanced Strength and Durability: The efficient polymerization initiated by LAP leads to materials with superior mechanical properties. Products cured with LAP exhibit higher tensile strength, better abrasion resistance, and improved durability, which is essential for high-performance applications in automotive, aerospace, and electronics industries.

Dimensional Stability: LAP-cured materials show excellent dimensional stability, maintaining their shape and size over time. This is particularly important in precision applications such as in the manufacture of medical devices and electronic components.

5) High Water Solubility

Solubility up to 8.5 wt% in water at room temperature

Enables formulation of aqueous photopolymerizable systems

a) Biomedical: Allows for cell encapsulation without organic solvents

b) 3D Bioprinting: Facilitates the creation of cell-friendly bioinks

c) Environmental: Reduces VOC emissions in coating applications

d) Cleaning: Easier equipment cleanup in industrial settings

6) Efficient Photoinitiator with High Quantum Yield

Quantum yield for radical formation: approximately 0.3

Rapid polymerization kinetics, reducing curing times

a) Increased productivity in industrial processes

b) Reduced oxygen inhibition during polymerization

c) Lower energy consumption in UV curing systems

7) Visible Light Sensitivity

Absorption peak around 375 nm, extending into the visible spectrum

a) Reduced UV exposure, beneficial for biological applications

b) Compatibility with LED curing systems, increasing energy efficiency

c) Deeper curing in thick or pigmented systems

d) Potential for use in phototherapy and bioimaging applications

8) Thermal Stability

Melting point around 220-225°C (with decomposition)

a) Use in high-temperature processing conditions

b) Improved shelf life of formulated products

c) Application in thermally challenging environments

9) Photostability

Resistant to photodegradation during prolonged light exposure

a) Improved long-term stability of cured materials

b) Consistent performance in outdoor applications

c) Reduced yellowing in clear coatings and adhesives

5. Safety

Storage: LAP should be stored in a cool, dry place away from direct sunlight and moisture. It is sensitive to light and heat, which can degrade its effectiveness.