Enhancing UV Protection in LED Technology with Carbon Dots: A Study on 3&4A-CDs Synthesis and Applications

1.Introduction

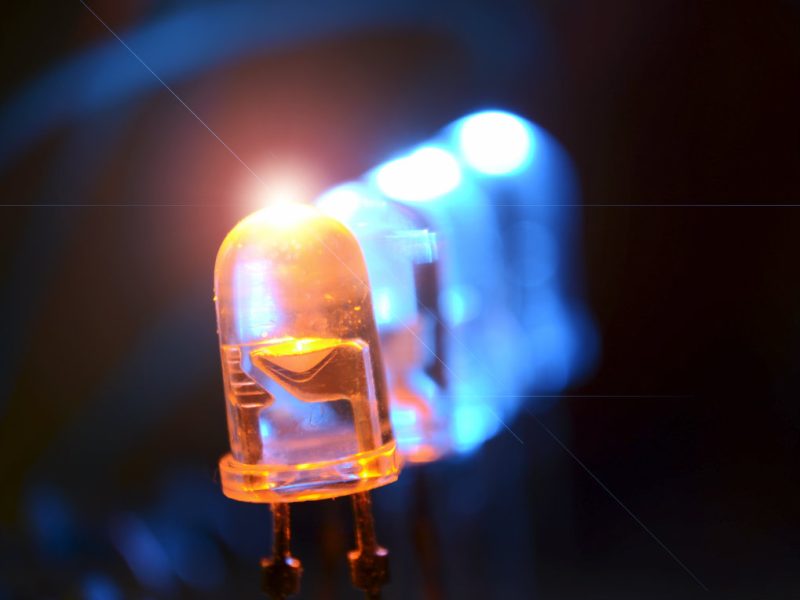

Light-emitting diodes (LEDs) have revolutionized lighting technology due to their advantages, such as compact size, low power consumption, and instant lighting. However, despite their efficiency, there is a potential risk associated with ultraviolet (UV) light leakage from LEDs. UV light, especially prolonged exposure, can cause various health problems, including skin pigmentation, photoaging, and other harmful effects. To mitigate this, the need for a robust UV-absorbing material is evident. Carbon dots (CDs) have emerged as a promising solution due to their unique optical properties, multifunctional groups, and extreme stability. This essay explores the synthesis and application of carbon dots, particularly focusing on the innovative 3&4A-CDs that exhibit exceptional UV absorption efficiency, making them suitable for UV leakage prevention in LEDs.

2.LED Technology and the Risks of UV Leakage

LEDs, widely used in everyday life, boast numerous advantages like energy efficiency, longevity, and brightness control. However, they also emit small amounts of ultraviolet light. While most LEDs are designed to emit visible light, a fraction of the emitted spectrum can fall within the UV range, especially in devices that generate white light through phosphor conversion.

The primary concern with UV leakage is its long-term health impact. UV rays, particularly in the UVA (320–400 nm) and UVB (290–320 nm) bands, are known to penetrate the skin, causing immediate and long-term damage. Prolonged exposure can lead to skin pigmentation, accelerated skin aging, and in some cases, increased risk of skin cancer. Given these hazards, it is critical to develop materials that can effectively block UV light while allowing visible light to pass through, preserving the LED’s functionality.

3.Carbon Dots (CDs) as a UV Absorber

Carbon dots (CDs) are a class of fluorescent nanomaterials that have gained attention due to their broad range of properties, such as strong UV absorption, chemical stability, low toxicity, and tunable fluorescence. CDs are characterized by their small size (typically less than 10 nm) and the presence of functional groups that enable interactions with a wide range of materials.

The unique properties of CDs make them ideal candidates for UV-absorbing applications. CDs can be engineered to absorb light across a broad spectrum, particularly in the UV range, making them perfect for addressing UV leakage in LEDs. Furthermore, CDs are environmentally friendly, cost-effective, and easy to produce, making them a viable solution for industrial applications.

4.Synthesis of A-CDs: A One-Pot Hydrothermal Approach

In this study, A-CDs were synthesized using a one-pot hydrothermal carbonization process. Hydrothermal carbonization is a widely used method to produce CDs due to its simplicity, low energy consumption, and ability to tailor the properties of the resulting carbon dots. By adjusting the precursor materials and reaction conditions, CDs with a wide absorption range (200–500 nm) were prepared, making them suitable for absorbing UV light in both UVA and UVB regions.

The hydrothermal method not only enables the production of CDs with excellent absorption capabilities but also ensures the stability of the material. A-CDs exhibit high chemical and thermal stability, which is crucial for long-term applications in environments where exposure to heat, light, and varying pH levels can degrade other materials.

5.Development of 3&4A-CDs: Optimizing UV Absorption

To enhance the UV absorption properties of the CDs, 3&4A-CDs were prepared using two different approaches: CDs mixing and raw material mixing. Both methods resulted in the production of carbon dots with average and efficient absorption in the UVA and UVB bands. The optimized 3&4A-CDs demonstrated superior UV absorption capabilities, absorbing light efficiently across the entire UV spectrum.

The efficiency of the 3&4A-CDs was further tested under various conditions, including accelerated aging experiments and pH variations. After 180 hours of accelerated aging, the UV absorption intensity of 3&4A-CDs remained above 97% and 99%, with no significant change in the emission wavelength. This indicates the stability and durability of the material, making it suitable for long-term use in LED applications where continuous exposure to UV light is a concern.

6.Synthesis of 3&4A-CDs@CMC Films for Enhanced UV Protection

Building on the success of the 3&4A-CDs, the next step involved incorporating these carbon dots into a carboxymethyl cellulose (CMC) matrix to form 3&4A-CDs@CMC films. The CMC matrix acts as a supporting medium, providing mechanical stability while allowing the CDs to retain their UV-absorbing properties. The resulting 3&4A-CDs@CMC films exhibited exceptional UV absorption efficiency.

A 0.45 wt% 3&4A-CDs@CMC film was shown to achieve 100% absorption across the entire UV spectrum, offering complete protection from UV light. Even after 180 hours of accelerated aging, the UV absorption intensity of the films remained above 95%, demonstrating the robustness of the material. The incorporation of CDs into a CMC matrix not only enhances UV absorption but also ensures that the films can withstand prolonged exposure to UV light without degrading.

7.Application in LED Technology

The primary application of 3&4A-CDs@CMC films is in preventing UV leakage from LEDs. By applying these films to LED surfaces, it is possible to block harmful UV rays while allowing visible light to pass through. This ensures that the LEDs maintain their brightness and efficiency without compromising safety. The extreme UV absorption efficiency of the 0.45 wt% 3&4A-CDs@CMC film, combined with its stability, makes it an ideal solution for preventing UV leakage in both indoor and outdoor LED applications.

In addition to their application in LEDs, the stability and efficiency of 3&4A-CDs@CMC films open up possibilities for their use in other areas where UV protection is necessary. This includes coatings for electronic displays, medical devices, and other equipment that may be exposed to UV light.

8.Environmental Impact and Cost-Effectiveness

One of the major advantages of CDs, particularly the 3&4A-CDs, is the simplicity and cost-effectiveness of the synthetic process. The one-pot hydrothermal carbonization method used to produce A-CDs is both low-cost and environmentally friendly, requiring minimal energy and producing little waste. Furthermore, the raw materials used in the synthesis of 3&4A-CDs are readily available and inexpensive, making the process scalable for industrial applications.

The environmental friendliness of CDs, combined with their excellent performance, positions them as an attractive alternative to traditional UV-absorbing materials, which may be toxic, expensive, or inefficient. The use of CMC as a supporting matrix further enhances the sustainability of the product, as CMC is biodegradable and non-toxic.

9.Conclusion

The development of 3&4A-CDs and 3&4A-CDs@CMC films represents a significant advancement in UV protection for LED technology. These materials offer excellent UV absorption efficiency, stability, and durability, making them ideal for preventing UV leakage without affecting the performance of LEDs. The simple, low-cost, and environmentally friendly synthetic process further enhances their appeal for industrial applications. As LED technology continues to evolve, the incorporation of 3&4A-CDs will play a critical role in ensuring the safety and efficiency of lighting systems in a wide range of applications.