Enhancing Thermal Stability and Fire Resistance in Ceramifiable EVA Composites Through Three-Dimensional Cross-Linking Structures

Introduction

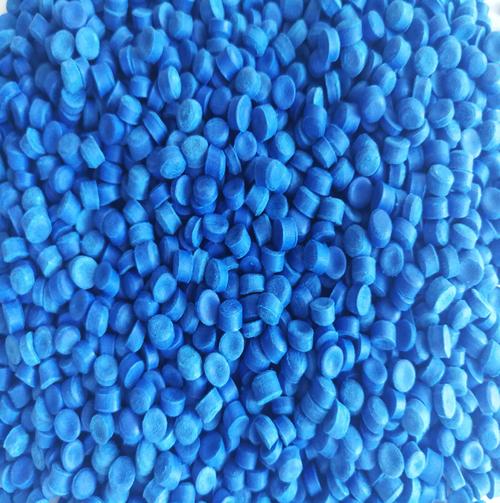

Ceramifiable ethylene-vinyl acetate (EVA) composites have emerged as a significant advancement in materials science, particularly in the field of thermal-resistant polymers. EVA-based composites are widely used due to their flexibility, impact resistance, and thermal stability, making them ideal for a variety of industrial applications. However, the need for enhanced thermal stability, especially under high-temperature conditions, has led to the development of ceramifiable composites. These materials, when exposed to elevated temperatures, transform into ceramic-like structures, maintaining their mechanical integrity and providing fire-resistant characteristics.

This essay explores the preparation of ceramifiable EVA composites using bis(tert-butylperoxy) diisopropylbenzene (BIPB) as a cross-linking agent, combined with silicate glass frits (SGF) and ammonium polyphosphate (APP) as additives. The cross-linking structures play a pivotal role in determining the thermal stability, rheological properties, and the self-supporting nature of the composite. By leveraging Fourier Transform Infrared (FTIR) spectroscopy, Differential Scanning Calorimetry (DSC), and gel content measurements, the cross-linking process is analyzed. The thermal and rheological properties are characterized using a rheometer and Thermogravimetric Analysis (TGA), and the ceramic residue’s porosity, phase composition, and morphology are examined through X-Ray Diffraction (XRD) and Scanning Electron Microscopy (SEM). The study highlights the influence of cross-linking structures on the composite’s ceramifiable properties, offering insights into the mechanisms that underpin the transformation from polymer to ceramic.

Cross-Linking Structures in EVA Composites

The incorporation of BIPB into the EVA matrix induces the formation of cross-linking structures, which are critical in enhancing the composite’s properties. Cross-linking is a chemical process where polymer chains are interconnected through covalent bonds, leading to a three-dimensional network. This network structure significantly impacts the mechanical and thermal properties of the material. In this context, BIPB acts as a radical initiator, triggering the formation of cross-links within the EVA polymer chains.

The formation of cross-linking structures was analyzed using FTIR, DSC, and gel content measurements. FTIR spectroscopy provided insights into the chemical changes occurring during the cross-linking process, with specific attention to the disappearance or appearance of functional groups related to the EVA matrix. DSC was employed to study the thermal transitions of the composite, particularly the melting and crystallization behaviors, which are influenced by the degree of cross-linking. Gel content measurements, which quantify the insoluble fraction of the composite, served as a direct indicator of the extent of cross-linking, with higher gel content correlating to a more cross-linked structure.

The role of SGF and APP in the cross-linking reaction was also evaluated. SGF, a commonly used inorganic filler, and APP, a flame retardant, were incorporated as additives to enhance the thermal stability and ceramifiable properties of the composite. However, the FTIR, DSC, and gel content analyses revealed that neither SGF nor APP interfered with the cross-linking reaction initiated by BIPB. This suggests that the additives primarily influence the composite’s thermal and ceramifiable properties without altering the fundamental cross-linking process.

Rheological Properties and Thermal Stability

The formation of a three-dimensional cross-linking network in the EVA composite has a profound effect on its rheological properties and thermal stability. Rheological properties, which describe how the material deforms under stress, are crucial in determining the processability and performance of polymer composites. The cross-linked EVA matrix exhibited improved rheological behavior, with increased viscosity and elasticity, as observed through rheometer testing. These enhancements are attributed to the interconnected network of polymer chains, which resist flow and deformation more effectively than a linear or weakly branched polymer structure.

Thermal stability, a key parameter for ceramifiable composites, was assessed using TGA. The cross-linked EVA composite demonstrated superior thermal stability compared to its non-cross-linked counterpart, as indicated by a higher decomposition temperature and reduced weight loss at elevated temperatures. The cross-linking structures contribute to this improvement by restricting the mobility of polymer chains, thereby reducing the rate of thermal degradation. Additionally, the presence of SGF and APP further enhanced the composite’s thermal resistance. SGF, as a glassy phase, provides a barrier against heat, while APP, as a flame retardant, releases phosphoric acid upon decomposition, promoting the formation of a protective char layer that insulates the material from heat.

Ceramifiable Properties and Self-Supporting Behavior

One of the most remarkable properties of the EVA composite is its ability to transform into a ceramic-like structure upon exposure to high temperatures, a phenomenon known as ceramification. This transformation is critical for applications where fire resistance and structural integrity are required. The self-supporting nature of the composite, which refers to its ability to maintain its shape and support its own weight during thermal exposure, is directly influenced by the formation of cross-linking structures.

The cross-linked EVA composite exhibited excellent self-supporting behavior, as it was able to retain its structural integrity up to 1000°C. This is attributed to the “skeletal” function of the cross-linking network, which acts as a scaffold, supporting the composite before the formation of inorganic crystalline phases. As the temperature increases, SGF melts and APP decomposes, contributing to the formation of a ceramic residue that replaces the polymer matrix. The combination of cross-linking structures and the ceramifiable additives ensures that the composite can withstand thermal stress without collapsing or losing its mechanical properties.

The apparent porosity and compactness of the ceramic residue were also investigated. The cross-linking structures played a significant role in reducing the apparent porosity of the ceramic residue, resulting in a denser and more compact ceramic structure. XRD analysis revealed the phase composition of the ceramic residue, identifying crystalline phases such as silicates and phosphates, which contribute to the material’s fire-resistant properties. SEM analysis provided detailed images of the ceramic residue’s morphology, highlighting the dense and interconnected structure formed after ceramification. The reduction in porosity and the enhancement of compactness are key factors in improving the material’s fire resistance and mechanical strength at high temperatures.

Conclusion

The development of ceramifiable EVA composites with three-dimensional cross-linking structures represents a significant advancement in the field of fire-resistant materials. The use of BIPB as a cross-linking agent, combined with SGF and APP as additives, results in a composite with superior thermal stability, rheological properties, and ceramifiable characteristics. The cross-linking structures, which form a robust network within the EVA matrix, play a critical role in enhancing the composite’s self-supporting behavior and reducing the porosity of the ceramic residue.

The findings from this study demonstrate that the cross-linking reaction occurs independently of the SGF and APP additives, allowing for the simultaneous improvement of thermal stability and ceramifiable properties. The ceramic residue formed after exposure to high temperatures exhibits reduced porosity and increased compactness, contributing to the material’s fire-resistant properties. These results highlight the potential of cross-linked EVA composites in applications where thermal stability and fire resistance are paramount.