Enhancing Adhesion of Acrylic PSAs with Silicone Urethane Dimethacrylates

Abstract

Acrylic pressure-sensitive adhesives (PSAs) exhibit satisfactory adhesion to high-surface-energy substrates but struggle with low-surface-energy materials. This study explores the synthesis and application of silicone urethane dimethacrylates (SiUDMAs) to improve the adhesion performance of acrylic PSAs on low-surface-energy substrates. By controlling the ratio of diisocyanate to polydimethylsiloxane (PDMS), various SiUDMAs were synthesized. The results indicate that the addition of SiUDMA significantly enhances the loop tack and peel strength of PSAs on challenging substrates, presenting a viable solution for industrial applications requiring strong adhesive bonds.

Introduction

Acrylic pressure-sensitive adhesives (PSAs) are widely used in various applications due to their excellent adhesion properties, clarity, and resistance to aging. However, the adhesion of acrylic PSAs to low-surface-energy substrates, such as polyethylene (PE), polypropylene (PP), and polydimethylsiloxane (PDMS), remains a significant challenge. This limitation hampers the performance of PSAs in many critical applications, including packaging, automotive, and medical fields.

To enhance adhesion to low-surface-energy substrates, various strategies have been employed, including the incorporation of surface-active agents and chemical modifiers. This study focuses on silicone urethane dimethacrylates (SiUDMAs) as potential modifiers to improve adhesion. The objective is to analyze the synthesis and application of SiUDMAs to overcome the adhesion limitations of acrylic PSAs.

Background

Acrylic Pressure-Sensitive Adhesives

Acrylic PSAs are characterized by their ability to form a bond upon contact with a substrate without the need for heat or pressure. Their adhesion mechanism is primarily attributed to the viscoelastic properties of the polymer matrix, allowing for the absorption of energy during the peeling process. While acrylic PSAs demonstrate high adhesion to substrates with significant surface energy, such as glass and metals, their performance on low-surface-energy materials is markedly inferior.

Challenges with Low-Surface-Energy Substrates

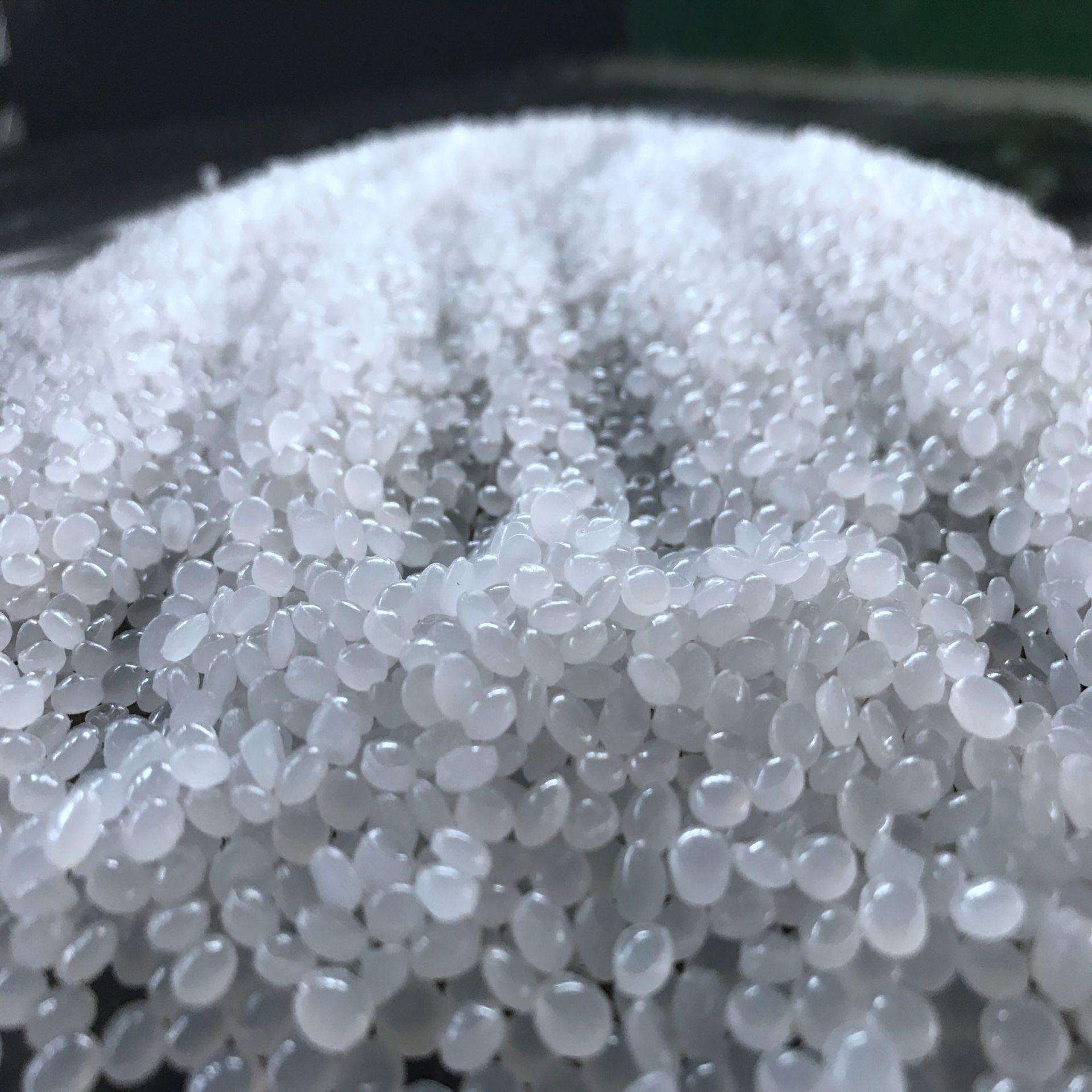

Low-surface-energy substrates, including PE, PP, and PDMS, present unique challenges for adhesion due to their non-polar nature, which reduces the wettability of the adhesive. This results in weak adhesive bonds that can lead to failure in practical applications. To address these challenges, modifying the chemical structure of PSAs through additives that enhance surface interaction has become a focal point of research.

Silicone Dimethacrylate (SiDMA)

Silicone dimethacrylate (SiDMA) has been utilized as a modifier to reduce the surface energy of acrylic PSAs. While SiDMA can improve compatibility with low-surface-energy substrates, it often leads to issues such as plasticization and miscibility problems, resulting in decreased peel strength. Thus, there is a need for alternative silicone-based modifiers that can effectively enhance adhesion without compromising the mechanical properties of the PSA.

Synthesis of Silicone Urethane Dimethacrylates (SiUDMAs)

Methodology

In this study, various SiUDMAs were synthesized by controlling the ratio of diisocyanate to PDMS. The synthesis process involved reacting PDMS with diisocyanate, followed by the addition of dimethacrylate monomers. The resulting products were characterized for molecular weight, viscosity, and surface energy.

Results

As the ratio of diisocyanate to PDMS increased, the molecular weight and viscosity of the synthesized SiUDMAs decreased. Conversely, the surface energy of the SiUDMAs increased due to the reduced PDMS content. This adjustment allowed for enhanced compatibility with acrylic PSAs, improving their adhesion to low-surface-energy substrates.

Performance Evaluation of SiUDMAs in Acrylic PSAs

Adhesion Tests

The adhesive performance of the modified PSAs was evaluated through loop tack and peel strength tests on PDMS substrates. The addition of SiUDMA2.0, which has a molecular weight similar to SiDMA, resulted in significant improvements in adhesive properties. Specifically, the loop tack increased by four times, while peel strength increased by six times compared to the control PSA.

Surface Energy Analysis

All types of SiUDMAs were found to lower the surface energy of the PSAs, significantly enhancing adhesion to PE, PP, and PDMS substrates. For instance, the PSA modified with 20 wt% of SiUDMA2.0 and cured at 200 mJ/cm² exhibited a peel strength of 520 gf/25 mm on the PDMS substrate, more than three times higher than the control PSA (138 gf/25 mm).

Thermal Stability

The thermal stability of the SiUDMA-modified PSAs was assessed using shear adhesion failure tests. The results demonstrated that the SiUDMA2.0-modified PSA could withstand temperatures up to 70 °C, exceeding the thermal stability of the control PSA, which was limited to 46.5 °C. This enhanced thermal performance indicates the potential for SiUDMA-modified PSAs in high-temperature applications.

Discussion

Mechanisms of Adhesion Improvement

The observed improvements in adhesion strength can be attributed to several factors. First, the chemical structure of SiUDMAs promotes better interaction with low-surface-energy substrates, increasing the wettability of the adhesive. Second, the controlled synthesis of SiUDMAs enables fine-tuning of their molecular weight and viscosity, optimizing the balance between flexibility and strength.

Comparison with Existing Solutions

Compared to conventional silicone-based modifiers, SiUDMAs provide a more effective solution to the adhesion challenges posed by low-surface-energy substrates. Their ability to enhance adhesion without compromising mechanical properties distinguishes them from previous modifications, such as SiDMA, which often led to trade-offs in performance.

Industrial Implications

The findings of this study have significant implications for industries that rely on strong adhesive bonds with low-surface-energy substrates. The ability to enhance the performance of acrylic PSAs using SiUDMAs opens new avenues for applications in packaging, automotive, and medical sectors, where reliable adhesion is critical.

Conclusion

The incorporation of silicone urethane dimethacrylates (SiUDMAs) into acrylic pressure-sensitive adhesives represents a promising strategy for enhancing adhesion to low-surface-energy substrates. The synthesis of SiUDMAs, coupled with their ability to improve loop tack and peel strength, positions them as superior alternatives to traditional silicone modifiers. Future research should focus on further optimizing the synthesis process and exploring additional applications of SiUDMAs in diverse adhesive formulations.