Enhancing Polypropylene Adhesion with Sustainable IBOA-Based Additives

Introduction

Polypropylene (PP) is a widely used polymer in the packaging industry due to its exceptional barrier properties, cost-effectiveness, and durability. However, despite its advantageous thermal and mechanical properties, PP suffers from poor surface energy, which makes it challenging to achieve effective adhesion of inks and coatings. This limitation is particularly problematic for printing applications, where adhesion quality determines the durability and functionality of printed materials. Addressing this issue, the present study explores the synthesis and characterization of novel non-halogenated functional additives based on isobornyl acrylate (IBOA) with acrylic acid (AA) and methacrylic acid (MAA) co-monomers.

Properties and Applications of Polypropylene in Packaging

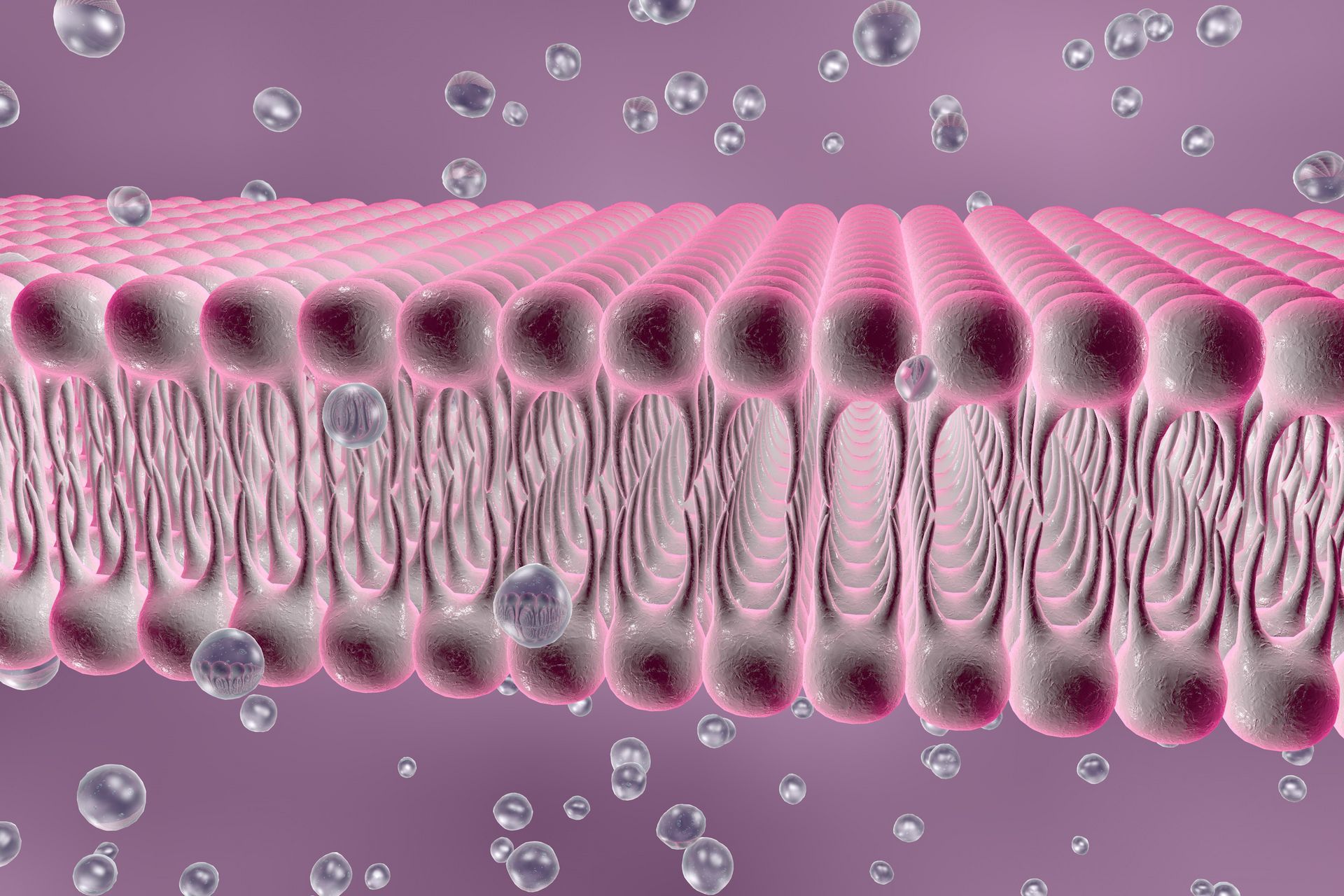

Polypropylene is a thermoplastic polymer with diverse applications in food and beverage packaging, pharmaceutical containers, and consumer goods. Its low density, high melting point, and chemical resistance contribute to its extensive use in hot-fill applications. Furthermore, its excellent moisture barrier and oxygen impermeability are highly valued in preserving product freshness and extending shelf life. However, the inert nature of PP surfaces impedes strong adhesion with inks and coatings, requiring surface modification or the use of functional additives.

Challenges in Printing on Polypropylene Substrates

PP’s non-polar, hydrophobic surface makes it inherently resistant to wetting by polar inks and adhesives. Traditional solutions, such as surface treatments (e.g., corona or plasma treatments) and primer coatings, improve adhesion but increase costs and environmental concerns. Non-halogenated functional additives offer a sustainable and efficient alternative to address adhesion challenges without requiring additional surface treatments.

Research Objective and Novelty

This study focuses on the synthesis and evaluation of IBOA-based copolymer additives, specifically IBOA-co-acrylic acid (AA) and IBOA-co-methacrylic acid (MAA). The unique structure of IBOA, characterized by its bornyl group, is hypothesized to enhance compatibility with PP surfaces through improved molecular interactions. By incorporating these additives into ink formulations, the study aims to improve adhesion on untreated PP substrates while maintaining environmental sustainability.

Synthesis of Functional Additives

The functional additives were prepared using oil-in-water emulsion polymerization, a versatile technique known for producing uniform polymer particles in a controlled environment. The hydrophobic nature of IBOA ensures compatibility with the non-polar PP substrate, while the carboxylic acid groups in AA and MAA facilitate bonding with ink components. The synthesis process was optimized to achieve desirable particle sizes and stability.

Characterization of Synthesized Additives

To comprehensively evaluate the properties of the synthesized functional additives, multiple analytical techniques were employed:

1.Dynamic Light Scattering (DLS) and Zeta Potential Analysis

Objective: Determine particle size distribution and colloidal stability.

Findings: Both IBOA-AA and IBOA-MAA copolymers exhibited nanoscale particle sizes, ensuring uniform dispersion in ink formulations. The zeta potential values confirmed good colloidal stability, essential for preventing sedimentation during storage.

2.Differential Scanning Calorimetry (DSC)

Objective: Assess thermal transitions and compatibility with PP substrates.

Findings: The copolymers demonstrated glass transition temperatures (Tg) conducive to maintaining flexibility and adhesion at typical processing temperatures.

3.Dynamic Mechanical Analysis (DMA)

Objective: Evaluate mechanical properties and adhesive strength.

Findings: IBOA-MAA exhibited superior storage modulus and adhesion strength compared to IBOA-AA, attributed to the structural rigidity of methacrylic acid.

4.Thermal Gravimetric Analysis (TGA)

Objective: Measure thermal stability.

Findings: Both additives showed high thermal stability, making them suitable for hot-fill applications.

5.Gel Permeation Chromatography (GPC)

Objective: Determine molecular weight distribution.

Findings: Narrow molecular weight distributions were achieved, indicating consistent polymerization and reproducibility.

Adhesion Testing on Polypropylene Substrates

The adhesion performance of the functional additives was evaluated using the cross-cut adhesion test. Ink formulations containing IBOA-MAA demonstrated significantly better adhesion to untreated PP surfaces compared to IBOA-AA formulations. This improvement is attributed to the stronger intermolecular interactions facilitated by the methacrylic acid moiety.

Comparative Analysis of IBOA-AA and IBOA-MAA

The key differences between the two functional additives lie in their chemical structures and resulting properties. Methacrylic acid (MAA) introduces a methyl group, enhancing steric interactions and rigidity, leading to better adhesion and mechanical strength. Conversely, acrylic acid (AA) provides flexibility but weaker bonding strength. These differences highlight the trade-off between adhesion performance and flexibility, depending on the application requirements.

Environmental and Industrial Implications

The development of non-halogenated additives aligns with the industry’s growing emphasis on sustainability and regulatory compliance. Halogenated compounds, commonly used for adhesion enhancement, pose environmental risks due to their persistence and potential toxicity. By offering a viable alternative, the synthesized IBOA-based copolymers contribute to greener and safer packaging solutions.

Future Directions and Potential Applications

The promising results of this study open avenues for further research and development:

Surface Modification Beyond PP: The applicability of IBOA-based additives can be extended to other low-surface-energy materials, such as polyethylene and polycarbonate.

Ink Formulation Optimization: Exploring different ink formulations to maximize compatibility and performance with the functional additives.

Scalability: Investigating the scalability of the synthesis process for industrial applications.

Conclusion

The present study demonstrates the potential of IBOA-AA and IBOA-MAA copolymers as effective non-halogenated functional additives for improving adhesion on polypropylene substrates. The comprehensive characterization of these additives underscores their thermal stability, mechanical strength, and environmental benefits. Notably, the superior performance of IBOA-MAA highlights its suitability for demanding packaging applications. This research provides a sustainable pathway to addressing adhesion challenges in the packaging industry, paving the way for innovative and eco-friendly solutions.