Green Solvent-Based Superhydrophobic PVDF Membranes for Efficient Membrane Distillation

Membrane distillation (MD) is an emerging technology for producing clean water from seawater desalination. The efficiency of MD systems largely depends on the properties of the membranes used, specifically their hydrophobicity. Superhydrophobic membranes, which minimize wetting and fouling, are essential for improving the efficiency and longevity of MD systems. However, current methods for preparing superhydrophobic membranes often involve toxic solvents and nanomaterials, raising environmental and safety concerns. This study investigates the use of triethyl phosphate (TEP), a green solvent, to fabricate polyvinylidene fluoride (PVDF) membranes using the recently developed spray-assisted nonsolvent-induced phase separation (SANIPS) method. The morphology, hydrophobicity, and performance of the resulting membranes are evaluated, demonstrating their potential for high-efficiency membrane distillation while addressing sustainability challenges. This paper explores the fabrication process, the membrane’s superhydrophobic properties, and its desalination performance, along with a detailed comparison to conventional nonsolvent-induced phase separation (NIPS) membranes.

Introduction

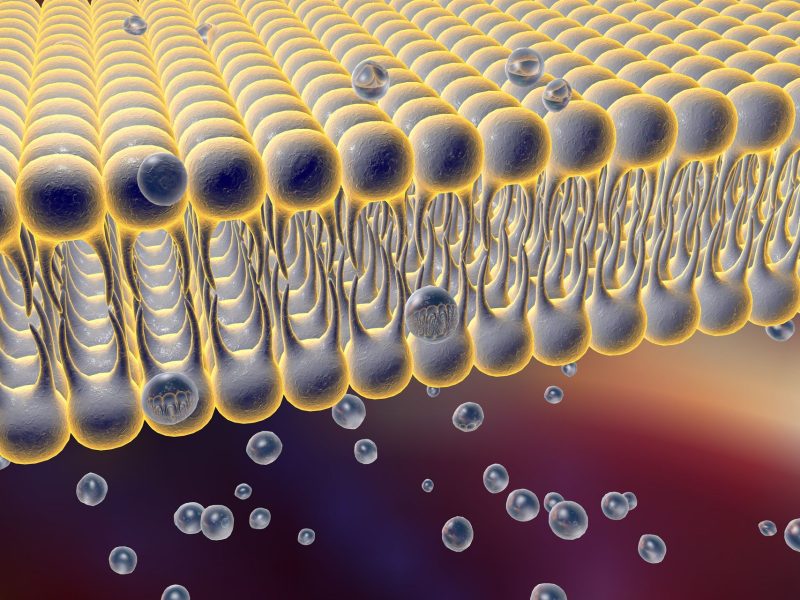

Water scarcity is one of the most pressing global challenges, with over 2 billion people currently living in water-stressed regions. Seawater desalination has emerged as a promising solution to provide fresh water, but the conventional methods, such as reverse osmosis, are energy-intensive and can be costly. Membrane distillation (MD) represents a promising alternative, relying on hydrophobic membranes to separate water vapor from saline feedwater under a temperature-driven gradient. However, the success of MD systems is heavily dependent on the membrane’s ability to maintain hydrophobicity during operation to prevent wetting, a phenomenon where liquid water permeates the membrane and compromises the distillation process.

The development of superhydrophobic membranes has garnered attention in recent years due to their ability to minimize wetting, enhance flux, and improve overall performance in MD systems. These membranes typically have water contact angles (WCAs) greater than 150°, which can be achieved by incorporating low-surface-energy materials such as nanoparticles or fluoropolymers into the membrane matrix. However, the preparation of superhydrophobic membranes often involves the use of highly toxic solvents and nanomaterials, which raises environmental concerns and limits their widespread adoption.

This study investigates an alternative approach to fabricating superhydrophobic polyvinylidene fluoride (PVDF) membranes using triethyl phosphate (TEP) as a green solvent, in combination with the spray-assisted nonsolvent-induced phase separation (SANIPS) method. The aim is to explore whether TEP can replace more harmful solvents like N-methyl-2-pyrrolidone (NMP) and produce membranes with superior hydrophobicity, performance in membrane distillation, and environmental sustainability.

Fabrication of Superhydrophobic Membranes Using SANIPS

1.Membrane Fabrication Process

The fabrication of hydrophobic and superhydrophobic membranes is typically achieved by a phase inversion process, where a polymer solution is cast onto a surface and then immersed in a nonsolvent bath to induce phase separation. In the case of PVDF membranes, the most common nonsolvent is NMP, a highly toxic solvent that presents significant health and environmental risks. As a green alternative, triethyl phosphate (TEP) was selected for this study due to its low toxicity, biodegradability, and low environmental impact.

The SANIPS method, an innovative technique developed to enhance membrane morphology and functionality, was employed to fabricate the PVDF membranes. In SANIPS, a polymer solution is sprayed onto a surface, and a nonsolvent is applied to the nascent membrane to induce phase separation while it is still in a nascent state. This spray-assisted process allows for better control over the membrane’s morphology and facilitates the formation of micro- and nanostructures on the membrane surface, which are crucial for achieving superhydrophobicity.

The preparation process in this study involved dissolving PVDF in TEP to form a dope solution, which was then sprayed onto a substrate to form a thin film. After spraying, water was applied to the nascent membrane for 45 seconds, before immersing it in a coagulation bath to complete the phase inversion. The resulting membrane exhibited a unique morphology with a rough, hierarchical structure, which contributed to its superhydrophobic behavior.

2.Comparison to Conventional NMP-Based Membranes

To assess the efficacy of TEP as a green solvent, PVDF membranes were also fabricated using NMP as the solvent under identical experimental conditions. The morphology of the membranes prepared with NMP showed smoother surfaces compared to those prepared with TEP. Additionally, the membrane made with TEP exhibited a much higher water contact angle (WCA) of 154°, compared to the NMP-based membrane, which had a WCA of around 120°.

This stark difference in hydrophobicity suggests that the choice of solvent plays a critical role in determining the membrane’s surface properties. TEP, due to its ability to produce a rougher surface with hierarchical microstructures, is more effective in promoting superhydrophobicity compared to NMP.

Characterization of the Membranes

1.Morphological and Structural Analysis

The morphological properties of the PVDF membranes were examined using scanning electron microscopy (SEM). Membranes fabricated using the SANIPS method exhibited a highly porous structure with a surface roughness that was more pronounced in the PVDF/TEP system than in the PVDF/NMP system. The hierarchical structure of the PVDF/TEP membrane, with micro- and nanoscale roughness, contributed significantly to its superhydrophobic nature.

In contrast, the PVDF/NMP membranes displayed a smoother surface with fewer microstructural features, which resulted in a lower water contact angle. The high surface roughness of the PVDF/TEP membranes was essential for creating the necessary surface tension that enabled the formation of the air-water interface, leading to the superhydrophobic behavior of the membrane.

2.Hydrophobicity and Self-Cleaning Properties

The hydrophobicity of the PVDF/TEP membrane was further evaluated by measuring the water contact angle (WCA). A WCA of 154° was achieved, indicating excellent hydrophobic properties. Additionally, the membrane exhibited self-cleaning properties, which were demonstrated by spraying water onto the membrane surface. The water droplets easily slid off the surface, taking away dirt and other contaminants, highlighting the potential of the membrane for applications where fouling and clogging could otherwise reduce efficiency.

Performance in Membrane Distillation

1.Direct Contact Membrane Distillation (DCMD) Test

The desalination performance of the superhydrophobic PVDF/TEP membrane was evaluated using direct contact membrane distillation (DCMD) with a high-salinity solution of 10 wt% NaCl. The results showed that the PVDF/TEP membrane exhibited significantly higher flux compared to the conventional NIPS membrane (22 kg/m²·h vs. 12 kg/m²·h). This enhanced performance can be attributed to the superhydrophobicity of the membrane, which reduces wetting and increases the vapor flux by minimizing the resistance to water vapor transfer.

The higher flux observed with the PVDF/TEP membrane is consistent with previous studies that have shown that superhydrophobic membranes can reduce the liquid-vapor interface resistance, resulting in more efficient mass transport in MD systems.

2.Long-Term Stability

The long-term performance of the PVDF/TEP membrane was also assessed. The membrane exhibited stable desalination performance over a period of 200 hours of continuous operation. This stability is attributed to the robust superhydrophobic surface, which resisted wetting and fouling, two major challenges in MD operations. In comparison, the NMP-based membrane showed a gradual decrease in flux due to the accumulation of liquid water and fouling on the membrane surface.

Environmental Sustainability and Future Outlook

The use of TEP as a green solvent presents a significant environmental advantage over conventional solvents like NMP, which are not only toxic but also difficult to dispose of safely. TEP is biodegradable and has a much lower environmental impact, making it an ideal alternative for producing membranes for water treatment applications. Moreover, the SANIPS method itself, being a low-cost, scalable technique, holds promise for large-scale production of superhydrophobic membranes without the need for toxic chemicals or complex processing.

The performance enhancements observed with the PVDF/TEP membranes suggest that they could be effectively used in large-scale desalination plants and wastewater treatment systems. Further research could explore the optimization of the SANIPS process, including the fine-tuning of solvent composition, spray parameters, and phase inversion conditions, to further enhance membrane properties and performance.

Conclusion

This study demonstrates the successful fabrication of superhydrophobic PVDF membranes using triethyl phosphate (TEP) as a green solvent, coupled with the spray-assisted nonsolvent-induced phase separation (SANIPS) method. The membranes exhibited excellent hydrophobicity, with a water contact angle of 154°, and showed promising performance in direct contact membrane distillation (DCMD) for seawater desalination, achieving a flux of 22 kg/m²·h. The membranes also exhibited stable long-term performance and self-cleaning properties, making them suitable for large-scale desalination and wastewater treatment applications. The use of TEP as a green solvent not only enhances membrane performance but also contributes to environmental sustainability by replacing toxic solvents like NMP.

Further research into the optimization of the SANIPS method and the incorporation of TEP in other polymer systems could pave the way for more efficient and environmentally friendly membrane distillation technologies.

Click Here to Go to the Product Page